The plant has the meaning to produce chlorine, caustic soda and sodium hypoclorite via brine electrolysis.

The three principal systems of the plant are:

1.Rectifying unit and electrolysis of the brine.

2. Brine preparations.

3.Sodium hypoclorite preparation.

The electrolysers feed by direct current produced by the rectifier, produce from the electrolysis of the sodium chlorure solution the following products:

- Chlorine which is used in hypochlorite section.

- Caustic soda mixed with exhaust brine (caustic liquor) that from the electrolysers is sent by gravity to the storage tanks.

- Hydrogen that is produced in the catodic side of the electrolysers and is collected to the atmosphere.

OUR PLANTS:

The increasing demand for on-site availability of limited quantities of chlorine, caustic soda and hydrogen to be used directly in their form or converted to sodium hypochlorite solution (bleach) and/or to hydrochloric acid solution , guided PFI to conceive and design small size bipolar electrolyzers to membrane and diaphragm able to match the market requirements. Taking for granted that the membrane bipolar technology is the primary technology to be considered for above purpose, the customers understand that the adoption of small size elementary cells assembled in a bipolar stack , compared to the large electrode (2,7 – 4.0 m2) most used in traditional chlor-alkali plants , allows a lower investment, even if more electrolysers are installed and grants a higher production flexibility.

This is why PFI provides customers with the unique modular membrane bipolar electrolyzer ELM 0.4, made in titanium and nickel able to fulfil the customer needs for small complete plants for on site production of few tens of ton of chlorine per day. This product represent the most advanced bipolar membrane technology for limited, small or very small production capacities and is the “hearth” of the plant offerred by our company.

HOW DOES IT WORK?

• The raw material fed to the cell is an aqueous solution of sodium chlorure (brine) at 300 g/l of concentration. It is fed inside the anodic side is called anolite.

• A special diaphragm divides anodic from the cathodic side. The solution inside it is called catholit.

• The brine flows through the cell is continous due to the difference of level between the two side of the cell (anodic and cathodic compart). When electricity passes, gas chlorine is formed at the anode and caustic soda and hydrogen at the cathode.

• The chlorine gas is produced on the anode of each cell then drawn to a general collector where is sucked to the absorption tower for the production of the sodium hypochlorite.

• Sodium hypochlorite is prepared by chlorination of a caustic soda/ exhaust brine solution of a proper concentration to obtain a stable product. The process is based on a “batch” production logic.

• The caustic soda/brine solution of proper concentration and at the temperature of 30-35°C is sent by means of the pumps to the absorption tower.

• One tank will be always under filling with fresh caustic soda/brine while the other tank will be in recirculation with the absorption tower.

• The chlorine produced from the electrolysers will be sucked by the adapted blowers (as to ensure a constant depressure outside from the electrolysers) and then in back current with the stream of caustic soda reacts forming sodium hypochlorite. The a.m. reaction product (sodium hypochlorite) is kept under recirculation until it reaches the wanted concentration.

P.F.I. is a well established company over the past 30 years with business transactions being carried out in several countries around the world. With regard to the electrochemical plants, since decades we are collaborating with a giant of the electrochemistry and probably the world leader in this field: Industrie De Nora spa.

We are currently using their activated anodes and we are one of the companies that are allowed to use their innovative, non asbestos, synthetic diaphragm with the commercial name of Polyramix, which compared to the classic diaphragm technology (asbestos) has enormous advantages:

• Large adaptability to different brine qualities.

• Lower energy consumption.

• High strenght sodium hypochlorite.

• Can be washed in order to restore the original permeability.

• Is harmless and environmental friendly, does not contain any restricted material.

(For more details please contact Industrie De Nora s.p.a. at the email address: alessandro.mozzillo@denora.com)

Thanks to the Polyramix diaphragm, P.F.I. developed an innovative vertical, modular electrolyser based on the well known ELM membrane electrolyser basis which finally permits the sodium hypochlorite production with a simple, reliable and user friendly configuration. The result is the possibility to produce on site small-medium (from 300 to 20.000 l/day) quantities of high strenght sodium hypochlorite (active chlorine concentration from 100 to 145 g/l). Before such results was possible to be achieved only adopting the membrane technology with all the limitations and difficulties due to this delicate media.

We of the P.F.I. have conceived, designed and manufactured a small size membrane bipolar electrolyzer ELM 0.4 in order to provide customers with a reliable, highly efficient and flexible device suitable to produce on site small (and also very small) quantities of chlorine, caustic soda and hydrogen to be directly converted, if needed, to bulk sodium hypochlorite solution (“bleach”) or to hydrochloric acid solution or used for any other required application.

Why bipolar? Because, due to the assembly of many elementary cells in the same stack, the bipolar arrangement results in a lower cost of hardware, lower power consumption, lower plant area allowing a easy modulation of the electrolyzer output through the number of elementary cells assembled in one stack.

Is simple and reliable. The ELM 0.4 electrolyzer is supplied assembled in standard modules “Chlorplus unit” whose outputs are: chlorine, membrane grade 32% caustic soda and hydrogen.

FEATURES:

• One module daily production (kg):

- Chlorine: 500-1500

- Caustic soda (NaOH): 564-1680

- Hydrogen: 14-42

• One module main raw materials consumption per metric ton NaOH:

- Salt (vacuum salt 99.9% NaCl): 1,5 ton

- Demiwater: 630 liters

- NaOH (100% basis): 60 kg

- HCl (100% basis): 90 kg

• Maximum output of “ChlorPlus” modularized units:

Production capacities beyond 3 tons per day may require the adoption of larger electrolyzers. Please consult P.F.I.'s commercial departement.

N.B. Each module is equipped with its own rectifier rated 1500-150 V. Depending on the customer's requirements concerning the maximum circuit voltage, two or three modules can be arranged in series to get 1 or 3 TPD Cl2 and fed from a single rectifier (a spare can be also provided) rated 1500-150 V.

• Maximum output of sodium hypochlorite from “ChlorPlus” units (litres per day)

Depending upon how the above products are combined one with the other the plant output is:

- 100/180 gpl available chlorine sodium hypochlorite solution

- 32% hydrochloric acid solution

- 32% NaOH solution

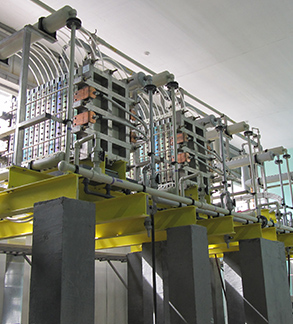

• Cell room configuration

The availability on site of such products eliminates the risks associated with their transportation and storage especially in countries with high ambient temperature.

The uses of above products are well known:

1. Sodium hypochlorite solutions:

- drinking, waste water and swimming pool disinfection

- tower cooling water disinfection

- pulp and paper

2. 32% hydrochloric acid solution:

any use in chemical plants, municipalities and industries (pH adjustment, cleaning, water treatment etc.).

3. 32% caustic soda solution:

any use in chemical plants, municipalities and industries.

4. Ferric chloride:

an important flocculant widely used for water treatment.

K-Chimie

Sevhimprom

Sevhimprom